Why 🔥 Burnt Outlets Are Dangerous

When installing EV charging, several critical factors must be considered to ensure the infrastructure's lifespan. The first is how to provide power to a parking space, which can be achieved by using an outlet or a hardwired charger.

Outlets are the most affordable and easy way to switch between charging options for drivers who might have a J1772 or NACS cable shipped with their vehicle. They’re also the most common way to charge an electric car, with over 75% of EV owners plugging into a 240-volt outlet at home a few nights per week, effectively waking up to a charged vehicle similar to your phone today!

There are many types of NEMA outlets worldwide, each providing different benefits for various applications. Many people install an overkill NEMA 14-50 or use one of the many adapters to plug into what they already have wired to their homes.

All the NEMA types a Tesla mobile connector can plug into.

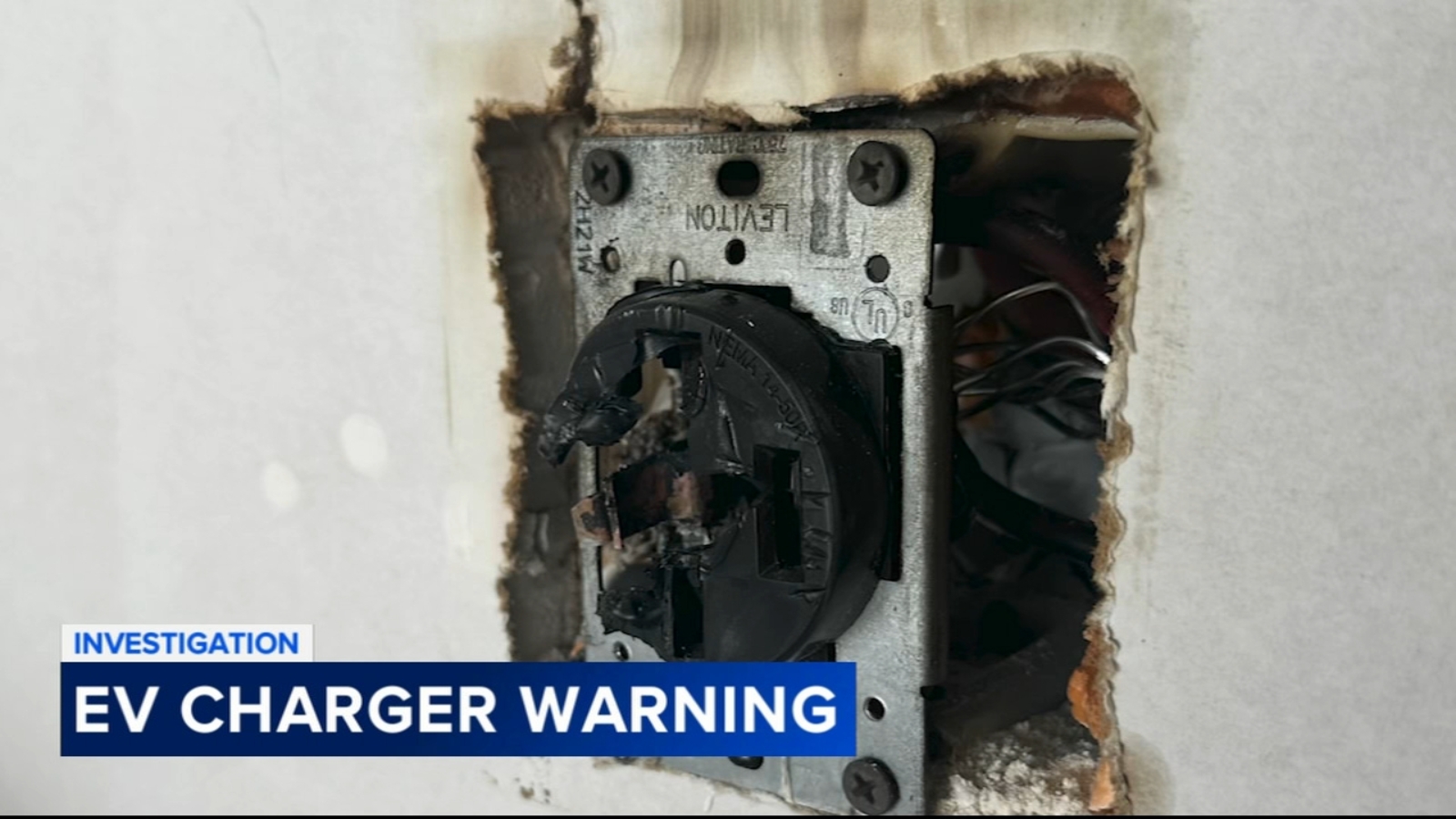

The issue is that not all Outlets are created equal, and most 240-volt outlets customers buy are only designed to be plugged into a dozen or so times for appliances like washers, dryers, stoves, refrigerators, etc. With lower duty cycles, these outlets wear out and pose a fire risk as they get used daily for EV charging. In Orange’s first year in business, two employees reported that the NEMA 14-50 outlets wore out and melted.

The outlet melted due to wear and tear, as it was a low-cost Home Depot $13 consumer-grade device. The same issues occurred, but here it also melted the cable to the charger. Their extension cord burned out, as it lacked temperature sensors to inform the onboard charger to stop pulling current. Due to the high resistance, the contacts get extremely hot from extended current draw, leading to complete melting.

This happens as the contacts inside, often made of cheap brass for consumer-grade outlets, wear out and apply less force to the plug after repeated use, allowing resistance to build up between the contact and plug. This resistance generates heat and often poses a fire risk. To reduce the risk, NO ONE should install anything less than an industrial-grade outlet for EV charging applications; these outlets are more expensive and designed for more duty cycles and high continuous current loads for industrial applications. They start at about $98 per plug for most applications and increase to $200 for high-end hospital applications, where reliability is critical for life. Then there are Orange Outlets.

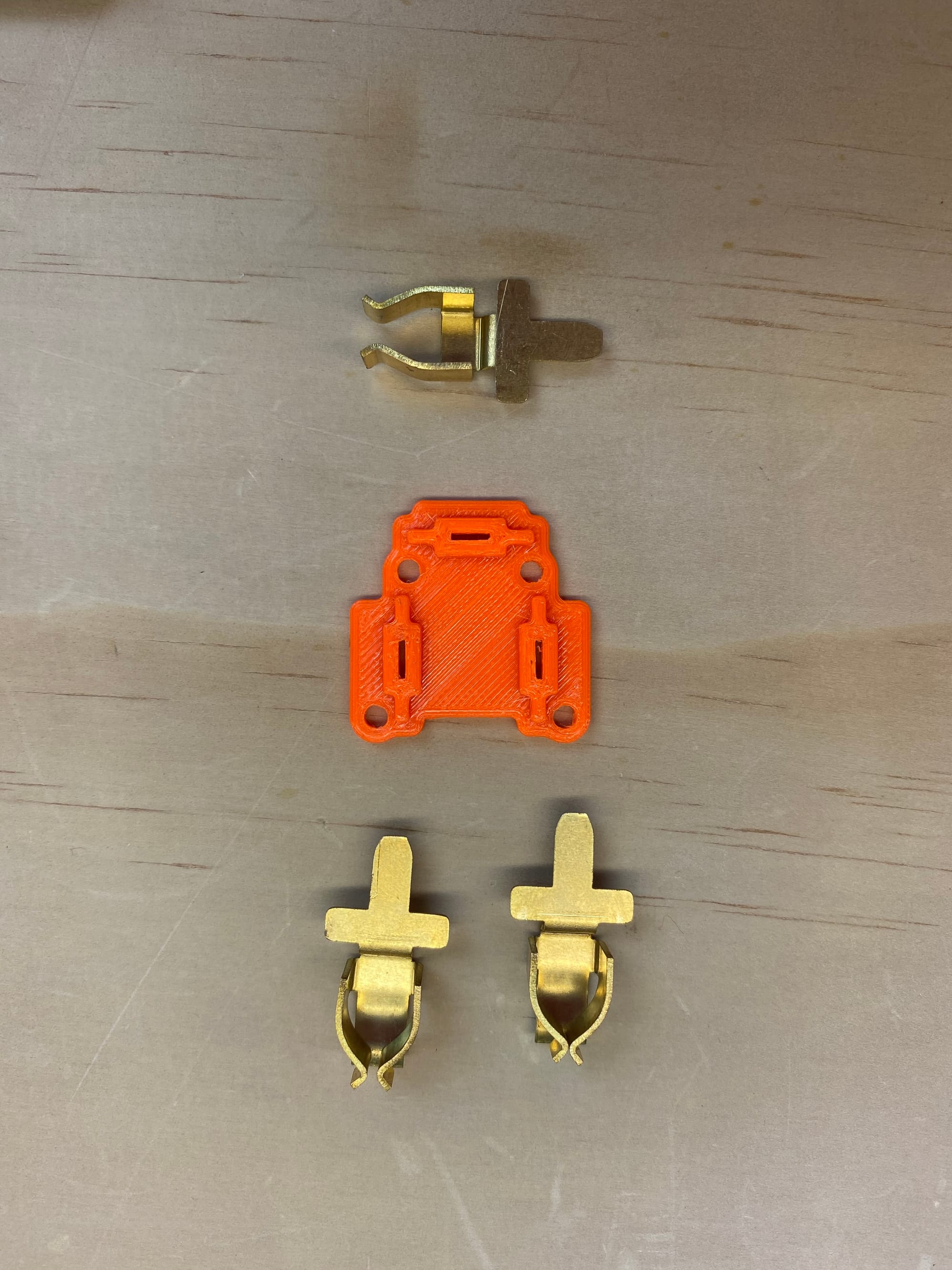

Orange Outlet exceeds the highest standards by being the first fully engineered Outlet, from day one, designed for use with Mobile connectors and exceeding UL 485 receptacle standards. Each outlet contact is made of copper beryllium, a material that exhibits a higher spring force and is more rigid, thereby preventing deformation over repeated use. Under UL485, an outlet can. It only has a mass insertion force of 13.5 pounds, which is designed to be 12.5 pounds of force. By using copper beryllium instead of brass, as most consumer outlets do, there is less overall resistance, as copper is more conductive than brass, further improving the design.

Pluggy II in action: We test a sample from each batch of contacts we get from our supplier to ensure quality.

Next is the physical geometry of Orange Outlets; we designed the receptacle from day one, knowing it had to last 10-plus years in the wild, and tested numerous designs. Using a robot called Pluggy, we could rapidly test the design in ten thousand cycles, seeing the force change over each cycle using a highly accurate force sensor behind the plug on the actuator arm.

Then there is the fact that Orange Outlets are smart, containing a current monitor inside for the energy grade watt-hour meter and networking chipsets to communicate the data. Each outlet has five temperature sensors, each at a critical part. The internal power supply, relays, and contacts have temperature sensors, and humidity and ambient temperature sensors track the external difference between internal and outside temperatures. This ensures that if any temperature exceeds a safe level, the relay will turn off and notify the user charging and the property manager of a possible issue long before any risk of fire.

We did this because, over the years, as early adopters of EV charging, we have seen many images of standard outlets wearing out and having stuff fall out of them, as well as burnt-up or melted outlets. By making fundamental decisions, there are no better Outlets on the market for EV charging in commercial settings.

You could install dumb outlets or even one of our competitors, who use off-the-shelf outlets for their products and don’t do the added engineering to ensure long-term reliability and safety. It’s your choice whether the risk of a possible electrical fire with standard outlets is worth the upfront savings.

At Orange, we won’t ever risk safety for simplicity or making an extra penny. Our exceptional engineers work hard to ensure we create the safest products possible; we don’t want our buildings burning down.

External Information:

6abc Philadelphia

6abc Philadelphia

Quora

Quora

Recent Writings

A Founder’s Reflection of 2025

By: Nicholas Johnson

A founder’s reflection on leaving Orange, the collapse and rebirth of energy markets, and why AI and infrastructure are entering a new phase in 2026.

Zero to One Through Great Customer Discovery

By: Nicholas Johnson

Over the last several months, I've been helping several other founders who are early or have had to pivot from their original idea. Each time I encounter the same friction or resistance from founders, I have been there myself, facing the pushback of talking with customers and asking

Three Quarters of Growth: What Orange Learned Building EV Charging for Multifamily

By: Nicholas Johnson

Context: A deep dive into Orange’s last three quarters—covering GTM execution, revenue growth, hardware challenges, and the unique dynamics of selling into multifamily properties. Focuses on business model design, utilization, connectivity, and why Orange’s approach is fundamentally different from traditional EVSE providers. Post Body: When we started